NEWS

Heidelberg: Hybrid production and Prinect Touch Free

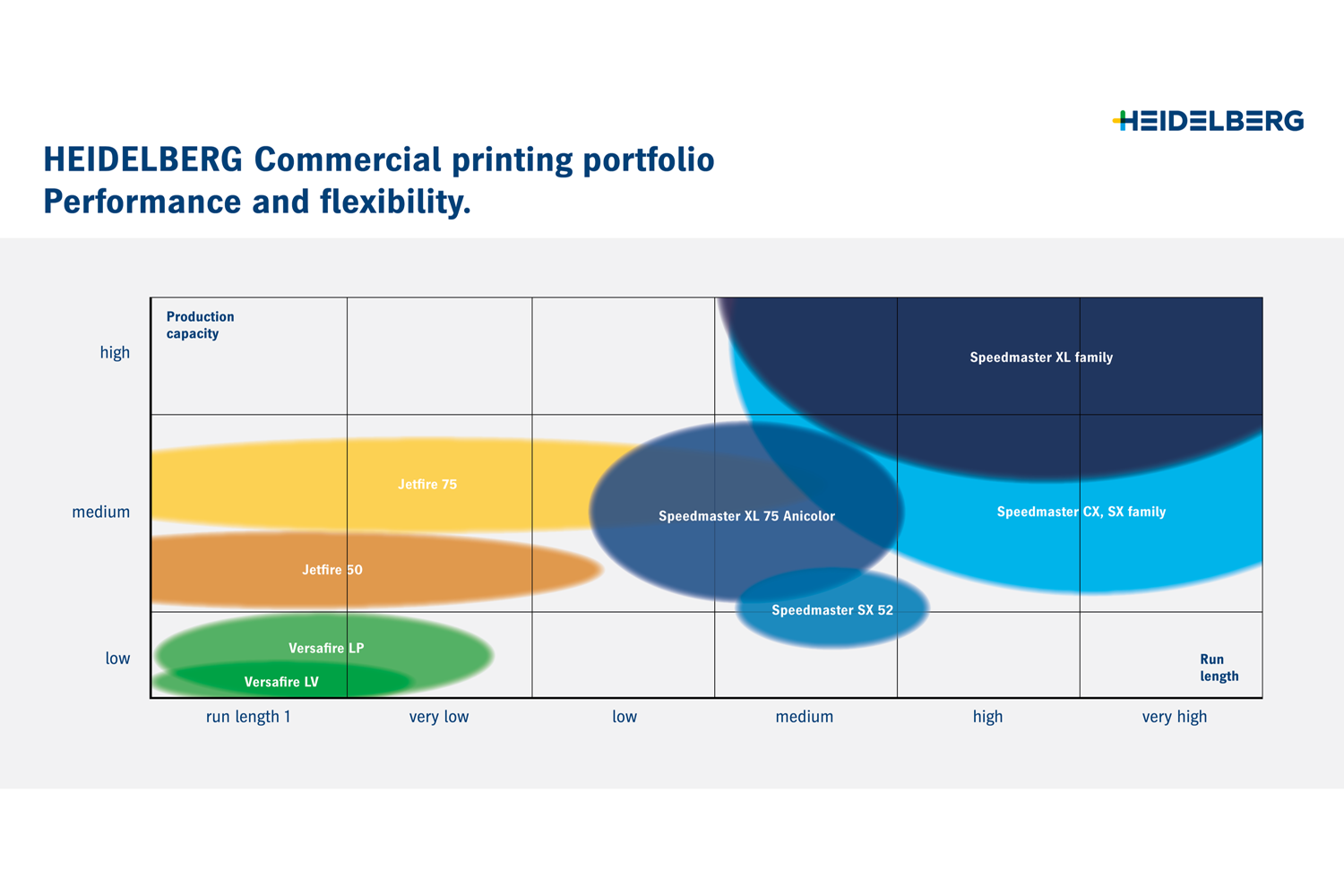

Analysis of the relevant press data has shown that around 65 percent of all commercial print jobs produced worldwide on a Speedmaster press from Heidelberger Druckmaschinen AG (Heidelberg) involve print runs of fewer than 2,000 sheets. However, some 90 percent of the print volume is produced on offset presses. Short or very short runs are produced digitally, while medium-sized and long runs are printed on offset presses. The two technologies therefore exist side by side and complement each other.

To handle this kind of order structure efficiently and cost-effectively, print shops combine offset and digital printing. They therefore need hybrid solutions that offer them maximum flexibility and create the conditions that enable them to produce the entire range – from very small to very large print runs – cost-effectively, with as little paper waste as possible, and on time, even when deadlines are very tight. Moreover, these users want a standardized workflow management solution that will enable them to process all orders with the greatest possible degree of automation. In addition to fast and cost-effective production, another key requirement is print results that are identical in color, irrespective of which print technology is used to produce the print job in question. Only then can production deliver the flexibility and performance that are needed to meet ever tighter delivery times.

Heidelberg supports print shops on a technology-neutral basis across the entire value chain

This is precisely where Heidelberg comes in, offering its customers a hybrid production environment across all technologies and fully integrated into one workflow with Prinect. “Nowadays, Heidelberg is a total solution provider and partner that can supply and integrate all the latest technologies on a technology-neutral basis and in line with customer requirements. We offer the entire spectrum – from toner to inkjet and from offset to flexo printing – all controlled from a common Prinect workflow,” says Dr. David Schmedding, Management Board Member for Technology and Sales at Heidelberg. “This is unique in the industry,” he continues.

The latest milestone to achieving this is the collaboration between Heidelberg and Canon for industrial inkjet printing that was announced at drupa 2024 and has attracted a great deal of interest on the market. With the Jetfire 50 digital printing system that is available now and, in the future, the Jetfire 75, which is currently still in the development phase, Heidelberg is offering its commercial customers a digital solution that meets industrial requirements in terms of productivity, flexibility, and quality. Both systems can be integrated into one workflow with Prinect Production Manager, as can the company’s sheetfed offset printing presses. Where necessary, Heidelberg also integrates digital printing systems from third-party manufacturers into the Prinect technology. Exactly the same rules always apply to the rendering of the print data and to color management, regardless of whether the job is being printed using digital or offset technology. This results in printed products that are identical in terms of color.

Greater efficiency and cost-effectiveness with Prinect Touch Free

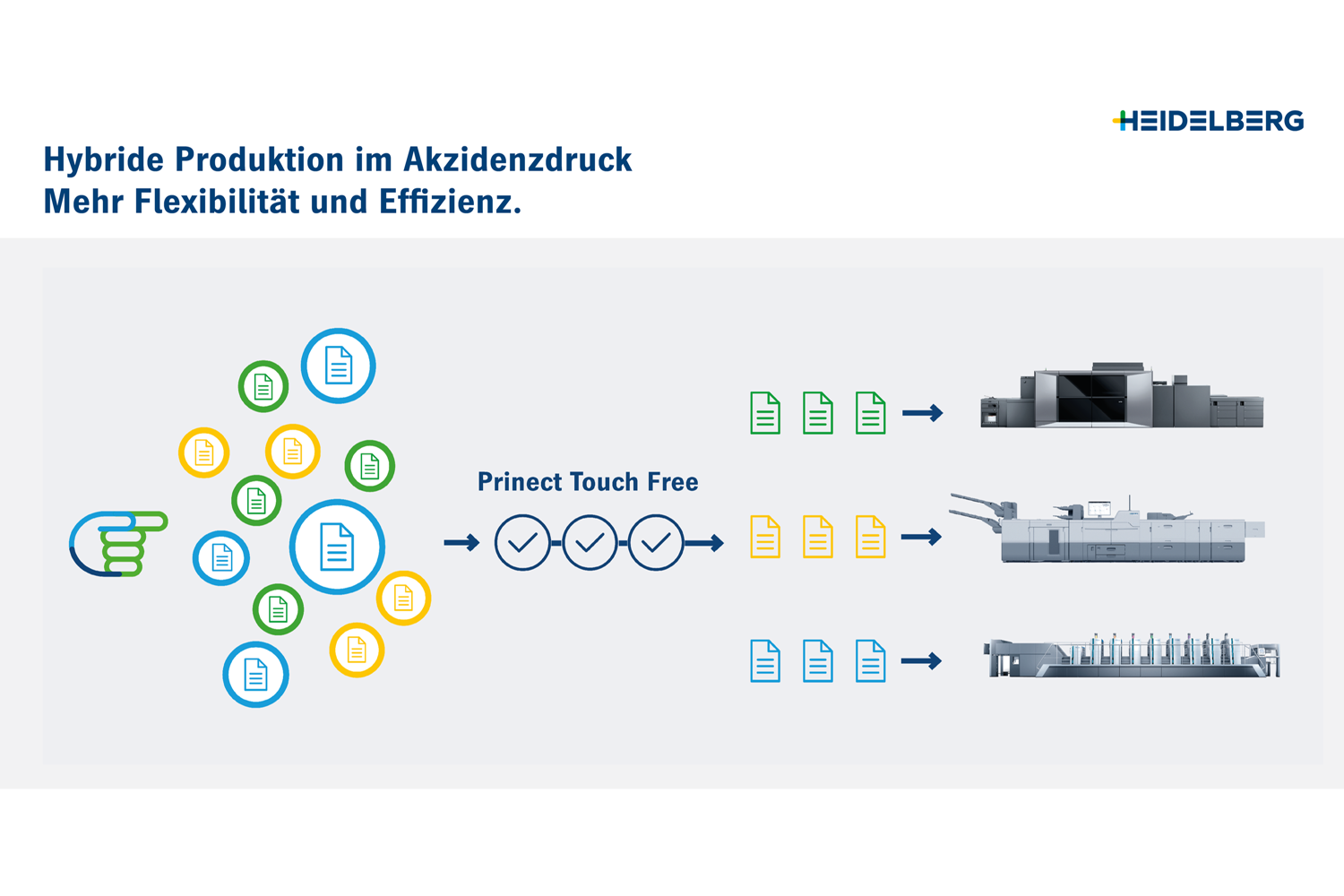

In a hybrid production environment with different presses and printing methods, it is even more important to keep necessary interventions in the production process to an absolute minimum. Each touchpoint comes at a cost in terms of time and resources, and there is an associated risk of error, too. Another issue is that the skills shortage in print shops is becoming even more acute. What’s more, the number of print jobs that need to be produced during a shift is rising, while print runs are getting smaller. Given these conditions and processes, staff are also reaching their physical limits. From an economic perspective, they can no longer handle this volume manually, especially since print shops are already experiencing high cost pressures and battling with low profit margins. For print shops to remain profitable, the production process needs to be as automated as possible – from the incoming order all the way through to the end product. The only solution is a workflow that is capable of managing the entire production environment as autonomously as possible. This is why Heidelberg developed Prinect Touch Free, which it showcased for the first time at drupa 2024. In conjunction with Prinect Production Manager, Prinect Touch Free autonomously steers print orders through the workflow in a hybrid production environment.

Prinect Touch Free automatically selects the most cost-effective production path

Supported by AI, the Prinect Touch Free native cloud software calculates all possible layouts autonomously and decides iteratively, on the basis of the complete order backlog, which method (offset or digital printing) represents the more efficient, more cost-effective production path that will also meet the delivery deadline. The software analyzes the order backlog and production key performance indicators on an ongoing basis, learns from this, and consequently optimizes the decisions made for future jobs.

In a first step, Prinect Touch Free is based on the app modules ‘Pathfinder’, ‘Decision Maker’ with ‘Batch Building’, and ‘Auto Scheduler’. Pathfinder works out all the production paths that are possible with the production technology available in the print shop. It draws up the relevant layouts and calculates the production costs for each possible path. By factoring in costs and the delivery date, Decision Maker decides which of the production paths identified should be selected, and it considers alternatives, too. In the Batch Building module, pending print orders are grouped together to minimize any machine changeovers and paper changes and also to optimize processes in postpress operations. Auto Scheduler is responsible for optimizing the production schedule on an ongoing basis.

What’s more, Prinect Touch Free takes account of postpress requirements and possible printing systems from third-party suppliers. It can handle even large order volumes with ease. It factors in the automatic scheduling as well as schedule changes in the event of machine malfunction or staff absence. The color management is adapted automatically for the output device in question, so there is no need for human intervention. With Prinect Touch Free, Heidelberg also offers users the future prospect of continued profitable print production – with output devices, whether offset or digital, and the workflow management system working hand in hand. Even today, Prinect Production Manager already fulfills key automation functions, ensuring perfect interaction in a hybrid production environment equipped with a Jetfire.

Print Media Center in Wiesloch is being revamped as the “Home of Print”

As part of its alignment as a total solution provider, Heidelberg is revamping its Print Media Center (PMC) at the Wiesloch-Walldorf site and turning it into the “Home of Print”. Offering the biggest exhibition space in the industry – more than 9,000 square meters of it – this Home of Print will give existing and prospective customers the chance to find out about all the latest technologies and solutions from Heidelberg for offset, digital, and flexographic printing on a technology-neutral basis. The revamp will be complete by the coming spring. By then at the latest, all the innovations showcased by Heidelberg at drupa 2024 for packaging, label, and commercial printing in fully integrated workflows and in customer-specific areas will also be available for live demos in the Home of Print. “In the Home of Print, Heidelberg will be showcasing the future of printing. There’s quite simply nowhere else customers can find out as much about the latest technologies for print production and work with our experts to explore and be presented with solutions that are tailored to their precise requirements,” Schmedding explains.